-

-

Colleges

-

-

Student Experience Greek Life Housing & Dining Health & Recreation Our Campus Community Engagement Athletics

-

Resources

Youngstown State University’s Excellence Training Center Advanced Manufacturing Services

Current List of Equipment

- Design for Additive Manufacturing (AM)

Modeling Software

- Geomagic Sculpt

- Solidworks

- Fusion 360

Simulation

- Autodesk Netfabb

- Ansys

- Metal AM

Binder Jetting

ExOne S-Max (Binder jetting for sand printing used for metal castings)

-

Materials: Silica Sand, Zircon, Cerabeads

-

Build Volume: 70.8 x 39.3 x 27.5 in (1,800 x

1,000 x 700 mm)

-

Layer Thickness: 280 microns

-

Axis Revolution: 100 microns

Image

Powder Bed Fusion

3D Systems ProX DMP 320

-

Build Volume: 10.82 x 10.82 x 16.53 in (275 x 275

x 420

mm)

-

Minimum feature size: 100 μm

-

Accuracy: ± 0.1-0.2 % with ± 50 μm minimum

-

Materials: Titanium, aluminum, Tool Steel, stainless

steel,

Nickle Alloys, and Cobalt Chrome.

Image

Xact

XM200G Metal 3D Printer-Single Laser/Standard

XM200G Metal 3D Printer-Dual Laser/Standard

-

- Laser spot size-100 microns

- Galvanometer-Standard

- Non-reactive Metals Only

- Extended Feed Cylinder

- Open Parameters for Powder and Application

- Spot Size 100 microns

- Galvanometer-Standard

- Non-reactive Metals Only

- Glove Box: Occupies Left Viewing Window

- Extended Feed Cylinder

- Open Parameters for Powder and Application Development

Image

-

- Polymer AM

Material Extrusion

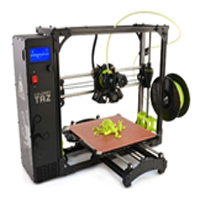

Lulzbot Taz 6 (Fused deposition modeling)

-

Build Volume (LxWxH): 11.02 x 11.02 x 9.8 in (280 x

280 x 250 mm)

-

Top Print Speed: 7.9 in/s (200 mm/s)

-

Average Print Speed: 1.18-1.97 in/s (30-50 mm/s)

-

Layer Thickness: 0.002-0.02 in (0.050- 0.5 mm)

-

Filament Size: 0.1 in (3 mm)

Image

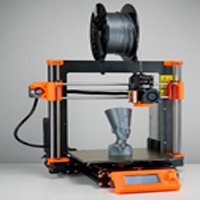

Prusa Mk3+ S (Fused deposition modeling)

-

Build Volume:

250 x 210 x 210 mm

or

9,84 x 8,3 x 8,3

in

-

Layer thickness: 0.05mm

-

Print Speed: up to 200mm/s

-

Filament size: 1.75mm

Image

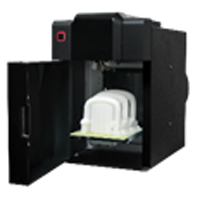

Stratasys Fortus 250mc (Fused deposition modeling)

-

Material: ABS

plus

-P430

-

Build Volume (XYZ): 10 x 10 x 12 in (254 x 254 x

305 mm)

-

Layer Thickness: 0.013 in (0.330 mm), 0.010 in

(0.254 mm), 0.007 in (0.178 mm)

-

Support Structure: Soluble

-

Achievable Accuracy:

± 0.0095 in (± 0.241 mm)

Image

Up mini (Fused deposition modeling)

-

Build Volume: (LxWxH): 4.7 x 4.7 x 4.7 in (120 x 120

x 120 mm)

-

Layer Thickness: 0.2/0.25/0.30/0.35 mm

Image

Markforged Mark Two (Fused deposition modeling, carbon fiber filament)

-

Build Volume: 12.6in x 5.0in x 6. (320mm

x 132 mm x 154 mm)

-

Weight: 35lbs (16kg)

-

Size: 23in x 13in x 14in (584mm x

330mm x 355mm)

-

Plastic Materials: Onyx, Nylon White

-

Fiber Materials: Carbon Fiber, Fiberglass,

Kevlar, High-Strength High-Temperature

Fiberglass.

-

Z Layer Resolution: 100 μm

Image

Filabot Filament Extruder (Filament fabrication)

Vat Photopolymerization

Formlabs Form 2 (SLA)

- Build Volume: 5.7 x 5.7 x 6.9in (14.5 x 14.5 x 17.5 cm)

-

Layer Thickness: .001-.012in (25-300 microns)

-

Laser Power: 250mW

-

Laser Spot Size: 140 microns

Image

-

- Material Characterization and Metrology

Metrology

245Kv GE Micro focus CT Scanner

- Please inquire for additional details

Image

3D Structured Light Scanner

- Please inquire for additional details

3D Scanner Creaform Handyscan 700

-

Scanning Area: 10.8 x 9.8in (275 x 205mm)

-

Resolution: 0.0020in (.050mm)

-

Accuracy: Up to 0.0012in (0.030mm)

-

Stand-Off Distance: 11.8in (300mm)

-

Part Size Range: 0.3-13ft (0.1-4m)

Image

- Post Processing

Machining

Manual and CNC Lathes

Manual and CNC Mills

Fanuc Model C600 iB 12” Wire EDM

Image

-

Maximum Workpiece Dimensions: 41.3in x 32.2in x 11.8in

(1050mm x 820mm x 300mm)

-

Maximum Workpiece Weight: 2204lb (1000kg)

-

XY Axis Table Travel: 23.6in x 15.7in (600mm x 400mm)

-

Z Axis Travel: 12.2in (310mm)

-

UV Axis Travel: 7.8in x 7.8in (200mm x 200mm)

-

Maximum Taper Angle: ±30°/150mm

Heat Treatment

Vacuum Sintering Furnace

-

Temperature max: 2600

°

C

-

Reserving Space at the

Excellence Training Center

Room reservations at the Excellence Training Center can be made Monday through Friday from 8:00 am to 5:00 pm. Reservations should be requested at least two weeks prior to the event; however, we will gladly assist you in planning a last-minute meeting, providing space is available. Internal YSU Faculty, Staff or Students, please use this Event Request Form to reserve space at the ETC. External requests can be made by calling 330-941-2357, Emailing ETC@ysu.edu or stop by the front desk to inquire.

ROOM RESERVATION COSTS

Rooms at the ETC can be reserved on both an hourly and daily cost. Costs range from $75 to $500.00. There may also be additional fees, too, if your event requires the building to be open beyond normal hours of operation. Other additional charges to consider are police / security service, parking fees and catering costs.

Jay Wargacki